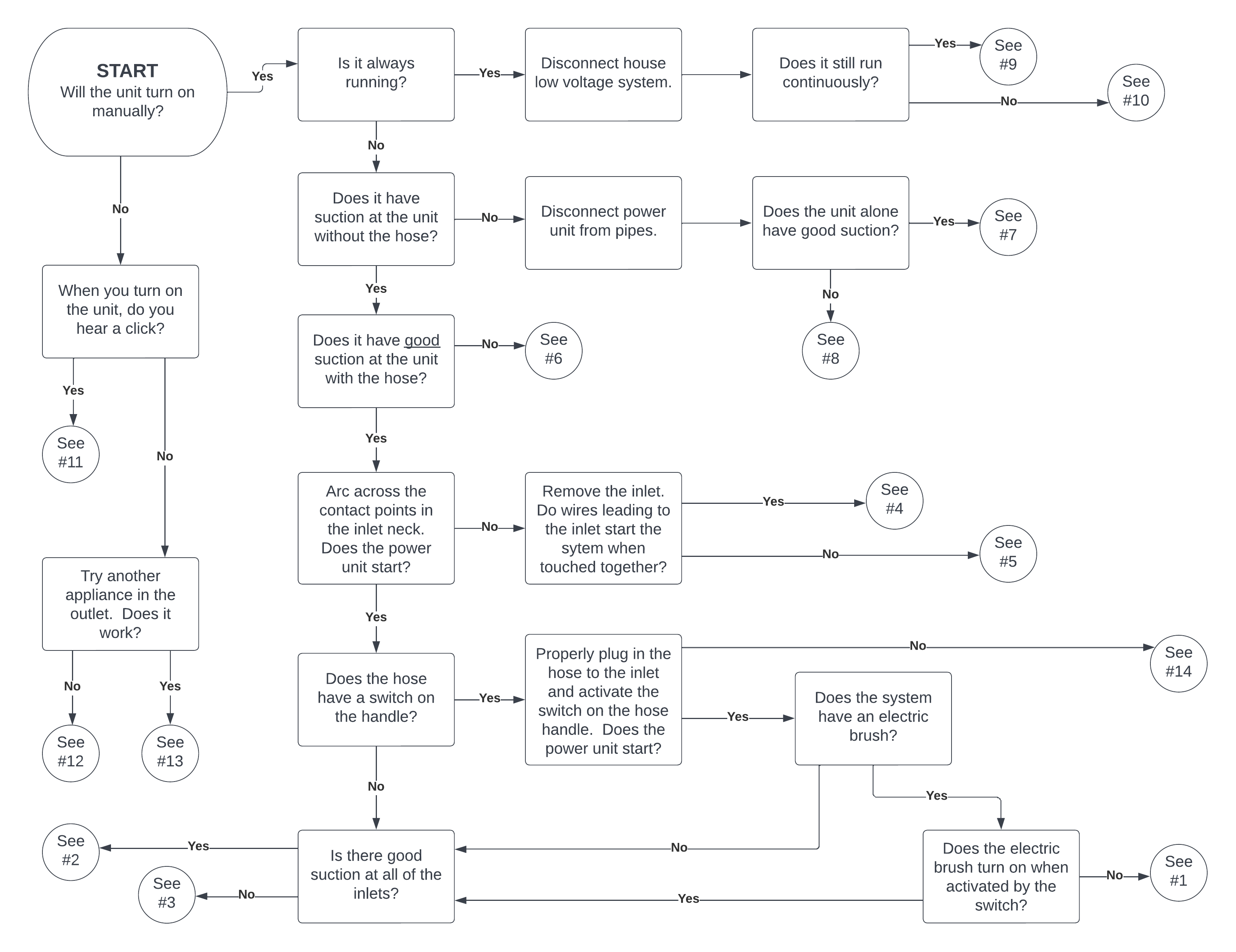

|

#1

|

Electrical Failure

|

-

If the inlets are Supervalves, plug the power brush directly into the valve. If the power brush works, the problem is the high voltage lines in the hose - likely a blown fuse in the hose, but also look at #14.

- Check brush for bad neck tilt switch or reset button.

- Put power directly to brush motor to see if the motor is bad.

- Check cord connections from hose to brush.

- Check to see that Supervalves/Electravalves have 110 volts.

|

|

#2

|

Clog Somewhere Else in the System

|

-

Check power brush.

- Check wands.

|

|

#3

|

Clog in Vacuum Tubing

|

- Check fitting just inside inlet and just inside of power unit for debris.

- Isolate exactly where the clog is - by running one styrofoam ball (each numbered) thru each inlet. Find which balls made it to the power unit.

- Reverse vacuum with another portable vacuum or built-in vacuum(disconnect the built-in vacuum from vacuum lines first.) Suck from the inlet valve is bad.

- Run electrician's fish-tape through and try to hook the object.

- Plug into inlet, put hand over hose end to build pressure, then suddenly release. Try this multiple times from various inlets.

- Run paper towel through as a "pigs" towards motor unit, then reverse suck with a portable to jar it.

- Run paper towel through from motor unit toward portable at non-functioning inlet.

- Very Important: Now run paper towel through all inlets and make sure they all arrive in power unit. If they don't, repeat the previous steps.

- If these solutions will still not free up the line - approximate where clog is and locate if accessible.

- Cut pipe and feel suction and visually inspect.

- Run paper towel through and listen for humming or vibration - possible nail in pipe or picture hung with toggle into pipe.

- Run small string through from motor unit to inlet with portable then tie heavier string - attach large object to heavier string. (Always tie a safety line to the large object to pull it back if needed.

- Locate exact location by creating noise with a ping-pong ball. Insert in inlet and turn on the unit(remove inlet to get the ball in.) Find the least obvious way of lifting flooring or cutting into the back of a cupboard or ceiling to access the clogged spot. Cut the pipe, remove the clog and patch the created access point.

- Run a paper towel through each inlet again.

- If only one inlet is clogged and cannot be fixed, relocate new pipe via existing installation method.

- Pipes that run underground can sometimes coagulate with debris from moisture.

- Route out with long blunt object.

- Run ten pounds of rice through system into unit, repeat.

- Trench old lines and replace.

- If lines run under a concrete driveway, relocate the power unit in area where accessible to locate.

- Re-route pipes from section that does work to section that does not work. Abandon any unnecessary lines.

- Check for "wrong way" Y's or T's.

- Was there any recent construction that might have driven nails into pipes? (Closet organizers, pictures, alarms, etc...)

|

|

#4

|

Bad Inlet - Replace Inlet & Plug Hose in Again

|

- Check to see if the old inlet is the same type with contact points. If not, it may have a push button that requires a latching replay.

- When replacing the inlet, look to see if the old one had tape on the inlet neck. If so, put tape in the approximate same location on the new inlet. When re-installing the vacuum, test for air leaks. If slight hissing is coming from the inlet, additional tape is required on the inlet neck.

|

|

#5

|

Low Voltage Wire Cut

|

- Was there recent construction done?

- Rat or mice issues?

- Is the garage detached with the power unit located in the garage? Has there been recent digging?

- Re-splice broken wire. (Coppers together and tins together.)

- Check wires on unit.

- Re-route wire from any working inlet or the power unit to any section of wire from the inlet that does not work. (Run under carpet, behind baseboards, stapled in corners or closets or down inside walls. Try to tie it to existing bad wire and pull it through.)

|

|

#6

|

Clog in Hose

|

- Reverse the hose at inlet on power unit. Suck it out.

- Drop kitchen knife or heavy object through hose - sling it or squeeze the hose and twist it to get it through.

- Shove a garden hose through the vacuum hose.

|

|

#7

|

Unit is Good, Pipes Have Leaks

|

- Was there recent work done on the house?

- Was there recent wallpapering or paneling done?

- Was the inlet removed or re-installed wrong?

- Is the inlet lid broken?

- Is there a hidden or forgotten inlet?

- Are there inlets installed in the floor? Have the pipes fallen down or come loose?

- Turn the power unit on and walk around the house listening for a leak.

- Is an inlet roughed in but not found on finish?

- Pipe running underground has a break in it.

- Recent gardening or tree has strangled underground pipe.

|

|

#8

|

The Power Unit Has Bad Suction

|

- If the power unit is multi-motored, are both motors working?

- Check power unit gaskets and look for cracks in the housing.

- Improper voltage into the power unit.

- Loose wires.

- Mini-breaker has malfunctioned.

- Cyclonic unit:

- Unit and debris in motor fan blades.

- Lint and debris on screen on intake.

- Too much back pressure from exhaust run being far. Something is blocking the exhaust line.

- Bag type unit:

- Excessive amount of very fine plaster dust clogging primary or secondary filter.

- Motor loose.

|

|

#9

|

Short in Power Unit

|

- Directly isolate low voltage leads alone (disconnect all auxiliary switches).

- Short in relay (very rare).

|

|

#10

|

Short in Low Voltage System

|

- Was there recent attic work or someone in the crawlspace?

- Has something chewed through the wire?

- Disconnect any splices you can find and check continuity of short.

- In a worst case scenario, re-route wire from any other working inlet or wire. (Possibly run the wire behind baseboard, under carpets, in closets or in air ducts.)

|

|

#11

|

Relay Getting Power but Not Starting Unit

|

- Most likely that the motor brushes need to be replaced.

- Isolate the motor and see if it works.

- Check the wiring from relay to the motor; does it go through mini-breaker?

- After replacing the motor brushes, if it won't take them, replace the motor.

|

|

#12

|

The Power Unit is Not Getting Electricity

|

- Check the house circuit breaker.

- Try the vacuum in another outlet.

- Is the circuit breaker the right size for the power unit?

- See what is on the circuit, is it overloaded?

- If necessary, have it inspected by an electrician.

|

|

#13

|

Transformer and Motor Not Getting Power

|

- Check the power cord, replace if possible.

- Bad transformer, check for spark between two low voltage wires out of transformer.

- Bad relay, check points, arc across to see if it solves it.

|

|

#14

|

Low Voltage in Hose is Not Working

|

- If the switch feels "mushy" then it needs to be replaced.

- Remove hose from wall and take apart the handle end. Look for lint or other debris in contact points.

- Make sure the hose is being fully inserted into the inlet.

- Hose may need to be replaced.

|